Instrumentation & Electrical

Got a question? We are here to help.

Mark Knowles

Director - Strategic Sales & Innovation

I&E Projects - Installation and construction

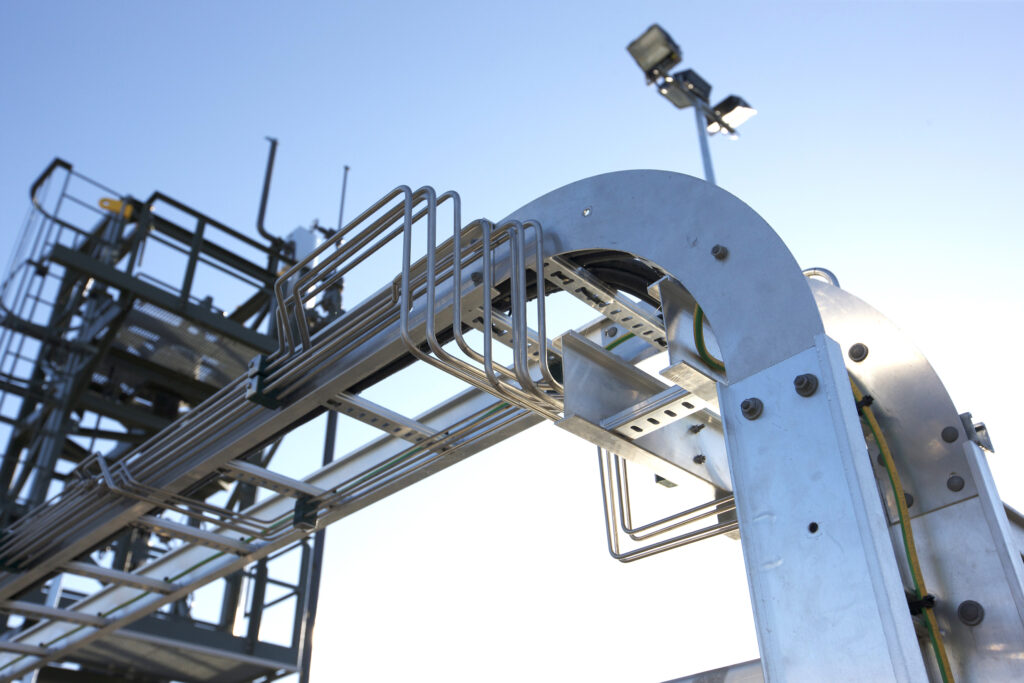

Instrumentation and Electrical (I&E) projects is the largest part of Entec's business, in terms of personnel and proportion of revenue. We're extremely proud of the size, breadth of skills and reputation of our instrumentation & electrical project capability. We focus on quality and safety, and on meeting our customers' expectations every time.

We've expanded and evolved our team to become as self-sufficient when on site as possible, minimising the involvement of multiple contractors and taking greater ownership of overall project execution for our customers. We've invested in training, tooling and plant to become our customers' trusted one-stop shop. But we also acknowledge we can't be all things for all projects; we've got a great network of specialist service providers that we collaborate with.

An I&E project may comprise 20 labour hours or 40,000 labour hours. We bring the same focus to quality and safety, irrespective of the project duration. Our I&E projects team is based in Taranaki - New Zealand's energy province - but about half of work is typically outside of the region, literally across all parts of the country.

We also excel at instrument tubing systems - pneumatic and hydraulic control systems. This is an increasingly rare offering in the market, an old craft that requires great skill and experience, but which is less commonly trained within the industry. Scroll down to the bottom of this page for more details on what our 'tubies' can provide.

We've expanded and evolved our team to become as self-sufficient when on site as possible, minimising the involvement of multiple contractors and taking greater ownership of overall project execution for our customers. We've invested in training, tooling and plant to become our customers' trusted one-stop shop. But we also acknowledge we can't be all things for all projects; we've got a great network of specialist service providers that we collaborate with.

An I&E project may comprise 20 labour hours or 40,000 labour hours. We bring the same focus to quality and safety, irrespective of the project duration. Our I&E projects team is based in Taranaki - New Zealand's energy province - but about half of work is typically outside of the region, literally across all parts of the country.

We also excel at instrument tubing systems - pneumatic and hydraulic control systems. This is an increasingly rare offering in the market, an old craft that requires great skill and experience, but which is less commonly trained within the industry. Scroll down to the bottom of this page for more details on what our 'tubies' can provide.

What is electrical instrumentation?

Entec installs and services all types of instrumentation, such as Electrical instrumentation and pneumatic instrumentation systems. Instrumentation systems measure temperature, voltage, pressure, flow, level and volume in industrial plants and facilities using measurement equipment and sensors. The electrical systems are the backbone of all industrial plants, providing everything from lighting and electrical reticulation at the point of use.

Entec’s instrumentation and electrical technician team is trade-certified and well-versed in electrical installation, inspection and maintenance of electronic instruments, pneumatic control and chemical dosing systems.

Entec’s instrumentation and electrical technician team is trade-certified and well-versed in electrical installation, inspection and maintenance of electronic instruments, pneumatic control and chemical dosing systems.

Instrumentation and Electrical Installation

Entec provides instrumentation and electrical installation in building construction sites, industrial process plants, mines, local government infrastructure and many other environments. Our high-calibre technicians and electricians provide state-of-the-art electrical installation and inspection. We ensure that our electrical installation and inspection adhere to industry codes and standards, promoting uniformity and safety across buildings, sites, and factories. Compliance with these regulations is crucial to preventing hazards, including electrical accidents and fires.

|  |

The breadth of our Instrumentation and Electrical skills and capabilities

We've grown the team on the back of repeat business and winning the project work of new customers over the years. We're very proud to include the following trades within the Entec I&E projects team;

|  |

Pneumatic control and chemical dosing systems

Entec’s I&E team has specialist expertise in the design, manufacture and installation of pneumatic control and chemical dosing systems.

A chemical dosing system is specialised equipment used to automatically inject precise amounts of chemicals into water or wastewater treatment systems to achieve specific treatment objectives, including disinfection and pH adjustment. The system usually comprises a chemical storage tank, a dosing pump, and a control system that oversees and regulates the chemical flow rate.

Our highly-trained experts, who are specialised in installing and instrumenting the electrical systems of a water or wastewater treatment plant, can also install a chemical dosing system. Since the dosing system is usually integrated with the electrical and instrumentation systems in the plant, it’s essential to have the same technicians responsible for installing all of these systems. We can help to ensure a seamless operation and quick resolution of any potential problems. Moreover, our Entec experts are proficient in both electrical and chemical systems and can guarantee safe and accurate installation, construction, calibration, and maintenance of the dosing system over time.

A chemical dosing system is specialised equipment used to automatically inject precise amounts of chemicals into water or wastewater treatment systems to achieve specific treatment objectives, including disinfection and pH adjustment. The system usually comprises a chemical storage tank, a dosing pump, and a control system that oversees and regulates the chemical flow rate.

Our highly-trained experts, who are specialised in installing and instrumenting the electrical systems of a water or wastewater treatment plant, can also install a chemical dosing system. Since the dosing system is usually integrated with the electrical and instrumentation systems in the plant, it’s essential to have the same technicians responsible for installing all of these systems. We can help to ensure a seamless operation and quick resolution of any potential problems. Moreover, our Entec experts are proficient in both electrical and chemical systems and can guarantee safe and accurate installation, construction, calibration, and maintenance of the dosing system over time.

Scope of supply

|  |

Applications

This means that when Entec carries out a calibration of one of these types of equipment, it can provide an IANZ stamped calibration certificate as evidence of the work performed. To repeat, this gives the customer confidence of the quality of the work performed. In many cases – particularly in the food and beverage sector – using an IANZ accredited service provider is mandatory.

Constructability review - adding value through experience

Here's a really quick illustration of how Entec's experience and broad skill base can offer real value to our customers' projects. A few years ago one of our regular customers went out to tender for the design/build/supply of 132 pneumatic emergency shutdown panels for deployment across a large gas production station. The scope entailed 15 different variations of panel, with an average weight of around 25kg.

Entec studied the scope from the point of view of constructability, and long-term maintenance requirements. Without compromising any functionality at all, we were able to refine the scope down to 7 different variations of the panel, with an average weight of 17kg.

This delivered to the customer;

- Fewer variants to hold on site as spares

- Lighter panels which were then able to be installed by a single technician when being replaced

- More efficient manufacturing and fewer components being used

- A saving of around 30% of the original estimated budget

Entec studied the scope from the point of view of constructability, and long-term maintenance requirements. Without compromising any functionality at all, we were able to refine the scope down to 7 different variations of the panel, with an average weight of 17kg.

This delivered to the customer;

- Fewer variants to hold on site as spares

- Lighter panels which were then able to be installed by a single technician when being replaced

- More efficient manufacturing and fewer components being used

- A saving of around 30% of the original estimated budget

|